The Tiny Kitchen

Bread & Lessons

You

Market baking. I’ve been doing this for almost five years. Beside mothering, this has been the best and hardest thing I’ve experienced. Diving into the deep end, not sure if goggles and nose plug would hold, lots of room for improvement, but I did it. I, however, was not and am not alone. You have been there with me from the start.

Amanda was first to listen and the one to pull that final pin, freeing me to move from only teaching to establishing my own commercial baking business. Continually, she has been encouragement, sharing ideas, sharing knowledge, the reason I generate emails using Kit. If I continue the metaphor, she had listened to me talk repeatedly about getting into the water, but she was the one who gave a gentle push.

Robin at 21 Acres brought me in as a contract baker, then offered me a pop-up location when I shifted to a Cottage Food Operation during Covid. She and the staff were stalwart supporters, giving me access to their customers, some of which still are. Robin introduced Bellevue Farmers Market Vivian to me when they needed a bread baker. Vivian took a chance that I would be able to increase production and gave me a space at BFM.

Vivian and Liz were excellent market managers: supporting, encouraging, lending hands, ideas and problem solving. My three years at Bellevue introduced me to a trove of customers, many who still pick up orders on Thursdays. I miss these faces but they have a permanent place in my heart.

During special market days, when a small troupe of vendors gathered on the 21 Acres patio, I met folks like Carol, the then Woodinville Farmers Market president. Carol, also a vendor, encouraged me to join the WFM. I spent two years-Thursday at Bellevue, Saturday at Woodinville. Carol continued to be a supporter and overall bright spot on market days, excited when she could get a loaf before sold out. When Carol had opportunity to sell at Lake Forest Park on Sundays, she took it. Monday after her first market there, I received an email from LFP Christina asking about my interest in selling at her market. Christina’s resident baker had retired so she was looking for a replacement. I was thrilled!

My first year with LFP was sporadic. I schedule my year in late December, early January. Most market applications are sent in January so all must be planned. I had scheduled time off, thinking there would be summer fun for the family. Instead, I filled those spots with Saturday dough days and Sunday markets. Christina was accommodating and supportive. I fell in love with this market. However, juggling three markets was crazy.

As a sourdough bread baker, the day before any market is dough day. Cookie dough, scone mixes, and even shortbread can be made ahead and frozen, but sourdough is demanding. Saying yes to a Sunday market meant leaving Woodinville. By this time, though, there were others ready to fill that gap and I continued my involvement as treasurer for the WFM Board.

As I became a weekly vendor at LFP, I began to meet the shoppers. LFP has shoppers-a fantastic community of folks who take their market seriously. Week by week I recognized faces, gradually learned names and got to share my love of grain and local flour with whomever stopped by. After my first full season at LFP, I decided to let Bellevue go, starting my current schedule of weekly porch pickups and a Sunday market. You, my LFP customers, are beyond. Naming only a few: Chris, Lynn, Greg, Ed, Pam & Steve, Mary & Mary, Robin, Larry, Kathleen, Nancy, Brian, Rashida, you brighten each morning, give meaning to the hard work and less than adequate sleep the night before.

When I ramped up production to sell at Bellevue, my niece Ann joined me in the kitchen. She was a new mom, so bringing baby to lay on the floor or be propped up on the over-stuffed chair while we worked was win-win. She made the pop tarts happen, mixed and portioned endless amounts of cookie dough, packed product for both Thursday and Saturday markets. She made it all doable, work days not feeling like work. We worked together weekly for 3 years. In 2025 she got a full time job managing meals at her daughter’s Montessori preschool. I thrilled for her but panicked for me. Ann also introduced me to my now chiropractor, Dr. Shea.

Dr. Shea practices chiropractic but focuses on the nervous systems, working to bring balance to the body. Whatever it all is, her adjustments made a world of difference for me. Things that felt insurmountable became doable. Clearer thought processes made doing the next thing easy. I no longer needed melatonin to fall asleep. Clarity came for letting certain things go. I stopped teaching at PCC, taking my classes home. Knowing I’d miss my co-workers, I have three who help out with packing up on market mornings.

Through all of this has been my family, Grant & Caleb. We would all go to 21 Acres on Thursday night to set up the tent for Friday. Caleb attended the Bellevue Market with me, helping to set up, supporting where needed, until Grant would meet us after work for a market dinner then tear down. Doing BFM & 21 Acres meant leaving Bellevue to set up at 21 before heading home. It was the two of them who set up Saturdays in Woodinville, then Sundays at LFP. Grant has always supported my dreams and plans, whether running my own school for homeschoolers (years ago!), teaching kids cooking classes at our home or turning our kitchen into a WSDA-approved baking space. He brings objectivity during our end-of-season recaps, wearing his managerial cap, asking me great questions. On stressful Saturday evenings when there was still work to do but I wanted sleep, Caleb would remind me “you’ve got this, Mom”, give me hug and ask how he could help. None of this venture would have happened without them.

Over all of this, my first pop up at 21 Acres was two weeks after my older sister passed away. Some would say not a great time to start a business. I would agree. Many of those first loaves were filled with grief and it showed. My little business, though, gave me a focus, one that she would have loved. It gave me a point of connection with several new customers. Having this seemingly inconsequential venue, having the conversations that ensued, were therapy. During year three, before Dr. Shea, I was able to feel the actual lifting of grief from my thought processes. Certain things became much easier, like having a hand-wash station in my booth. I’m not sure I would have had awareness but for this task I had undertaken.

As this calendar year ends and my 5-year anniversary approaches, I know I’m lucky. I have worked really hard but I am lucky all the same. I am lucky to have met you, to have worked with you, to have talked and hugged and been supported by you. To everyone who bought a loaf of bread, who felt gaga about the biscotti, who gobbled up the coffee cakes and pies-thank you! For each of you who came to my classes, who tried hard, laughed, chatted and ate-thank you! Thank you, to each of you, from the bottom of my heart.

On Being Tiny

In 2008, after I got a new computer that could actually do things on the internet, I started blogging on WordPress. I first wrote about my garden, then cooking, baking and how I was teaching folks to do the same. My kitchen was small and while it had a slight updo in 2016, is still small by most standards. I posted under In My Tiny Kitchen, but when it came time for a domain name of my own, most things Tiny Kitchen were already spoken for. My favorite tiny kitchen website (beside my own) is for the very literal tiny kitchens!

The leap to Cottage Bakery in 2021, spotlighted how small my production space was. A Washington State Cottage Bakery must be established in a home kitchen. Flat surfaces are always a premium in a food space, but covering sinks with cutting boards and using the vertical space of sheet pan racks go a long way in freeing up elbow room. Bringing in metal work tables and occasionally employing the dining table give me most of the space I need. Converting the laundry room to ingredient/equipment storage, while also installing a 3-part sink, has taken more pressure off the kitchen proper.

I create a lot of product in my Tiny Kitchen. To get it all done for baking day, my best tools are the freezers. Mixing, shaping then freezing cookie doughs, prepping then freezing dry mixes for scones, having pie or pie dough or filled pop tarts all frozen ahead of time makes those items a reality for markets. I have production notes for each day of the week, not really having any one entire day off, at least not during the summer market season. Some days are more scheduled than others, some days are quite long. Working from home, there can be days full of interruptions, leaving me finishing tasks well after bedtime. On these especially long days, it is nice to have such a tiny commute.

As I write this, there are only three regular season markets left for 2025. The season has been a blur, but one studded with lovely customers, diligent co-vendors, kitchen helpers who have made me successful. We have crunched numbers for becoming larger. A commercial space would require more product to cover new expenses, requiring regular employees to produce that product, attending more markets to sell that product or establishing wholesale accounts. After all of that is done, though, my bottom line would be about the same as it is now. I don’t think that kind of push is what I want to do. I’m lucky for having this business, for getting to do what I’ve wanted for years. I’m lucky for market managers like Christina, for all the folks who order weekly for porch pickups, for Spouse and Junior who work relentlessly each Sunday to get The Tiny set up. Baking is hard work but it’s good work. Thank you for giving me the opportunity.

Together

Last weekend, Spouse & I celebrated our 39th wedding anniversary. The Willamette Valley, with its beautiful wines, welcomed us with open arms. The weather was perfect, the Riesling delicious, and I’m still thinking about the fiddlehead ferns included with our Saturday lunch. I think we’re lucky. I know I’m lucky to have this person on my side.

Being a small business owner, an owner of a very small business, means that everything is mine to do: I develop recipes, test those recipes, prep, shape & bake, package & deliver. I imagine labels, packaging, market displays; inventory ingredients, practicing first in/first out. I renew licenses, handle accounting, transition the kitchen from home to business and back again, and, I wash a lot of dishes. When I pivoted to this iteration of The Tiny Kitchen, I really didn’t know how exhausting it would be.

I started this new business during Covid, just a few weeks after my beautiful older sister passed away, but I knew this was what I wanted to do. Things started out rocky but because of the enthusiasm from customers, because of the amazing people I met on a weekly basis, and because of the support of my partner, things have grown and developed. Spouse has always supported my ventures, my dreams. Those of you market-goers may have met him bringing me coffee or lunch, setting up or tearing down the booth, checking in throughout the day. We have occasional business meetings during the year, going over what’s working/what’s not. He brings his objective managerial self and asks me great questions. We create the year-long calendar together, choosing what dates I won’t be at a market for self care. In 2024 he got his food handler’s permit so he could help with packaging loaves or shortbread or whatever needed to be done in the flurry of a pre-market morning. He spends most of his Sundays during market season at my beck and call. I’ve not expected this from him and am so grateful for all he adds to The Tiny.

This year my employees are shifting to new, better, bigger endeavors. I’m thrilled for them and know they’ll pop back in whenever they can, to get more pie dough into the freezer. I am rethinking my offerings, rethinking quantities produced, and rethinking my market attendance to ensure a more sustainable future for me. This summer, I want to have a few more free evenings to spend with Spouse on the patio with a glass of rosé, rather than pinned to the 3-part dish sink. I want to finish my days at a reasonable hour, maybe actually having sat down for dinner. I want to finish the season tired but not broken. I love baking for my customers and 16-hour days are common for bakers, but this season I’m going to work on a sustaining practice. I know my partner will support me in this as well.

Partners

Never Too Late

One of the pivotal voices in my parenting was that of John Holt. John Holt’s early writings centered on how children learn, how they fail and how to support a life long love of learning. His work was positive, inspirational, and doable. One of his last books to write was a memoir of how he learned to play the cello as an older adult. In it, he shares his frustration, his persistence, his joy at working on this task he had long wanted to do. He eventually became proficient enough to play in the community orchestra near his Boston home. Though he hadn’t started lessons as a child or youth, he was able to make this dream a reality.

When someone wants to learn about dough, improve their handling skills, make pie, shape buns, learn techniques for better cookies, this is all possible, regardless of your age. It helps to have hands large enough to hold common tools, to have strength enough to wield a rolling pin, to be tall enough to reach the mixer, but even these potential drawbacks can be mitigated. YouTube and Instagram are bulging with content to teach all us anything we might want to know. We can prop our screen against the flour bin and get our hands dusty and doughy.

Sometimes, though, a community is needed. Sometimes there needs to be a community settled around a table or along a counter, gathered with the same goal: learn or improve a new skill. Our Bread Camp this past weekend was just such a community. Five participants joined, two with more experience, two with some experience, and one with no experience. The two with the most experience were friends, commuting far enough from home requiring overnight stays at a local hotel. Their camaraderie was infectious, quickly drawing the others into their circle of laughter. There is much information given during these Camps and the volume can be overwhelming. The brand new bread baker had the support of the other four who augmented, underscored, encouraged with their own experiences, while they themselves received new ideas and reinforcement for their own loaves. There was no competition, no verbose overlording, just a desire for making better bread.

This is why I teach. Though exhausted after each session, I said goodby to the students Sunday afternoon, enriched well beyond the amount of tuition. My heart was full, my mind was full, including new ideas received from my group. My work space was a mess but that’s what today is for. I want folks to be successful with any class they take with me. If that success comes with laughter and light, my job cannot be any better. I started The Tiny Kitchen nine years ago. I started the Cottage Bakery arm only 4 years ago. I wanted to do this and I did. It’s hard work, but it wasn’t too late to follow this dream. I am lucky for it.

What do you want to do?

Margin

Our bakery is small. Our name: The Tiny Kitchen, is not an under- or overstatement. We are tiny. Even though we’re small, we want to be mighty. Mighty here means that every choice made needs to be sincere, needs to be thoughtful, and needs to provide the most impact that we can manage. A very large part of our choice is where our flour comes from. A bakery wouldn’t be without flour. The flour could be the cheapest possible, it could gluten-free, it could be all white, all whole grain, all ground on site. We are proud of the flour we choose to use.

The majority of our flour comes from Cairnspring Mills in Burlington. This mill was opened in 2016 as a sister mill to Camas Country Mill in Eugene, Oregon. Camas Country was the first regional mill to operate in the PNW in 80 years when it opened in 2011. At the time, most of the grain grown in the PNW was shipped out of the country. Camas changed that, causing a ripple effect across the USA. With resources and encouragement from The Bread Lab in Burlington, local grain is once again farmed, milled and used in bakeries throughout the PNW and across the country.

This resurgence of local grain, of a local grain economy, is allowing farmers to get the most from their farmland. Rather than their crops being lost amongst tons of grain from who-knows-where, getting commodity prices affected by fickle market variables, they are closer to earning a sustainable living. These farmers are not just growing grain in the dry-farmed areas of eastern Washington, but also in the Skagit Valley, on the Olympic Penninsula, and even in the San Juan Islands. The grain that’s being harvested has a story, a story of the people growing it, the people who pluck nuisance wild rye by hand, who plant by drilling into the soil to avoid erosion, who have strict guidelines to protect the precious top soil, who don’t use harmful chemicals, people with families, multi-generational farms, trying to grow sincere food. These are the people we work to support.

When you buy our scones, you’re enjoying the labor of Moon Family Farm in Horse Heaven, Washington. This flour is milled at Cairnspring and is our flour for scones and all things pie. When you eat most of the cookies we make, you’re experiencing Edison all-purpose, grown by Washington Bulb Company, and others, in the Skagit Valley. Early on, the Bread Lab worked with Skagit growers, encouraging them to plant this grain in that field fallow from bulb or potato rotation. If it worked, they’d get “people food” prices rather than “animal food” prices for that year. It worked. Our whole grain shortbread? That grain is grown and milled by Bluebird Grain Farms in Winthrop. Our bread uses Cairnspring flour, but we augment with whole grain from Moon Family Farm that we grind here, and with flour from Chimacum Valley Grainery on the Penninsula. Our products are delicious because we start with flour that has flavor, flour that has natural, specific baking qualities, flour that has a story.

We have always held that the food we produce should nourish everyone involved. We choose ingredients that are usually more expensive because we want folks to earn a living wage, whether flour from the Skagit Valley or chocolate from South America. Small farms and small producer coops give better access for us to know where our dollars are going. We choose organic eggs, butter and sugars. We know the vanilla we use is responsibly sourced. As a Cottage Food Operation, we don’t spend much on rent so that’s a savings we pass onto our customers. This year we may need to tweak some offerings, use a little less chocolate, not bring those brownies quite so often, work to not over produce on any given week, make adjustments to avoid price changes for as long as possible. We could earn more profit if we cheapened things up, but margins are not as important to us than the marginalized. People should be paid for the work they do, for the goods they produce. We are proud to support farmers, to bring their hard work to your table.

At the start of our fourth year with this Covid-pivot version of The Tiny Kitchen, we don’t know what the future holds. We don’t know how the farmers markets will go. We don’t know if you’ll be able to show up. We do know we will continue to do our part to support local growers and millers with our Tiny Kitchen. Thank you for your support, your smiles, conversations and kudos. We are lucky indeed.

New

In so many ways, the start of a new calendar year is only that: a new calendar. With my schedule posted on a computer desktop or phone app, I don’t have the joy of that new paper calendar each year, often a holiday gift, selected just for me. The holiday break at the year end provides some closure to old and welcome to new, but that’s it? Everything just chugs along the same as it ever was. Where’s the new?

Primarily a Market baker, we at the Tiny do get to hold new in January. Our big bakes don’t begin until May leaving time to finish up the books, get our permit & licenses renewed, and develop new offerings. As a Cottage Food Operation, part of our process is to have all items approved by the WSDA before we can produce them. Labels must be created and vetted by our inspector. Having the gist of a recipe is easy as ingredients are listed by volume. Fine tuning those ingredients into a Tiny Kitchen product takes time and brain energy. This is what we’re doing now.

Since our labels must be approved ahead of time, much thought goes into what we might want to make at anytime during the year, what items might be seasonal, what customers might want to try. New variations of scones, biscotti, shortbread are on deck. We’re adding granola and quick breads to the roster, as well as a new chocolate rye cookie – yum! All of the new needs to be fine tuned and finished by end of April. Folks who order from our mailing list will get first dibs on new as we offer up what’s available any given week. This is hard work but good work, fun work when we enjoy our successes with a cup of coffee. Happy New Year!

Dough Day

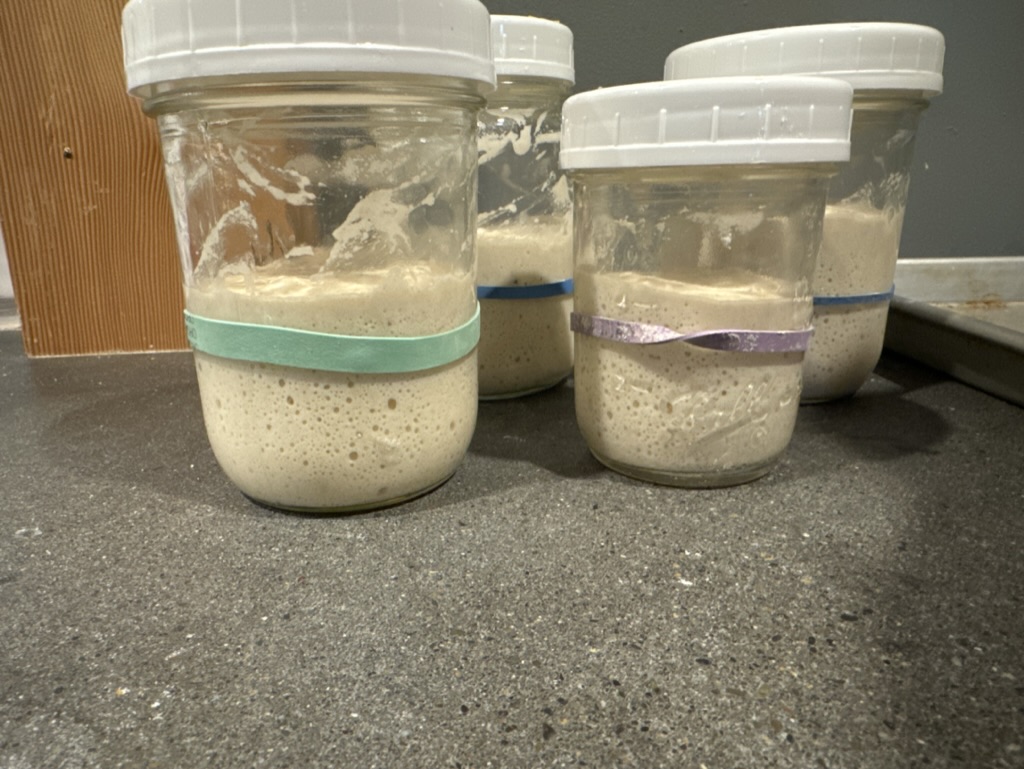

Each day before a market, I am immersed in dough. After feeding larger quantities of starter the night before, I wake to see if that starter is ready or does it need more time. If it needs more time, I put it into a warmer environment to increase fermentation. While I wait for it, I prepare the levain containers for three of the loaf varieties. Levain is more starter, but fed to be ripe in only a few hours rather than overnight. It is considered “young” and is the engine for the PNW Country, Expresso and Whole Grain loaves. My Tangy loaf is fed straight starter from the overnight rest. This usually gives the loaf more of the quintessential sourdough tang.

Once the levains are mixed and left to ferment, I mix the big batch of Tangy loaves. This initial mix starts the trajectory of my day. I will be stuck in, chained to my kitchen from that point until early in the evening, if all goes to plan. Making bread feeds my soul. The processes of dough day to the pulling of loaves from the oven, while not compulsion, have become something I must do. That being said, I often dread dough day, knowing everything is fixed without variation: measuring correctly temperatured water, initially mixing dough before the mandatory autolyse rest, finishing that mix adding the levain, more water and salt. Setting timers to dictate stretches & folds & temperature checks is followed by mixing a different batch, starting the process anew in each bus tub. The little chalkboard has start times and estimated preshape times so things don’t jumble together at any point. One person can only process so many loaves before the subsequent batches sit too long, verging on over-proof. It can feel like tyranny. It is the tyranny I dread. This tyranny begins to subside when that batch of Tangy loaves is shaped, resting cold in bannetons for the night. One down, three to go. Satisfaction begins to seep in around the edges of my mind and heart.

Most folks have no idea the time and effort that produce naturally-fermented, hand-mixed, hand-shaped bread. They may balk at the price tag of $8 to $10. I overhead one market visitor say “$9? I could make that for 2.” I silently invited him to do so. I silently invited him to give an entire day of his life, to give his mind and muscles to the process, to increase his anxiety as to the ready-ness at each step, to put his faith in the process: the time and the temperatures, the touch and the texture of the dough, for $2. “Yeah. Knock yourself out.”

At the start of this dough day, I saw a quote from Jeffrey Hamelman. Jeffrey H. is a (one of the few in the USA) Certified Master Baker, former head baker at King Arthur and author of Bread: A Baker’s Book of Techniques and Recipes, and an occasional contributor to the Bread Baker’s Guild of America’s online forum. He offered this after composing it for the opening words at a conference. These words are why I do what I do, why I endure each and every Dough Day. I leave you with them.

Before there is a loaf there is a baker. Before the baker there is a miller. Before the miller there is a harvest. Before the harvest there is planting and tending. Our bread begins with the farmer. The farmer and the baker are the beginning and the end of the visible bread; they are great pillars of sustenance, of profound importance to society. The chain of grain at last leaves the hands of the baker and the bread continues its journey into countless bellies, before it again enters the earth and the cycle begins anew.

The breath of our ancestors is in each loaf.

When someone offers you a slice of bread, look her in the eyes and take it with both hands.-Jeffrey Hamelman, Certified Master Baker, author of Bread

Magic Number

“The past and the present and the future, the faith and hope and charity, the heart and the brain and the body…”

Schoolhouse Rock, Three is a Magic Number

The importance of three was brought to light for many of my generation through the music of Schoolhouse Rock. A table needs three legs to stand, triangles have three corners, three sides and three angles, and when you add a baby to an expectant couple, it makes three. I know that Junior made our family magic when we became three.

Along with all of the ancient trinities, there lies flour and water and salt. When combined, these three insignificant ingredients undergo an alchemy like no other. Yeast, bacteria, enzymes, gluten strands, flavonoids, crust, crumb, texture, taste and comfort are all by products of this Magical Three. Each time I remove loaves from the oven, each time I slice into a just-cooled loaf, each time I note the rise and fall of the starter, I’m amazed. The farmers growing beautiful, flavorful grain; the millers turning that grain into flour like no other; the bakers using that flour to create products with flavor beyond yeast or add-ins are another trinity. Bread is a symbol of life, life stemming from an ancient trinity. Three is a magic number.

Seasonal

Wheat is not usually thought of as a seasonal ingredient. It’s not like dark red cherries, perfect peaches or truly vine-ripened tomatoes that, especially here in Western Washington, have a very short window of exquisite flavor, of texture, of color, of all the things. The wheat I use, most of it milled for me, but some I mill myself, does have limited life. Only so much of any one varietal is grown each year. Therefore, there is only so much available to be shipped to the mill or to me. When the organic Edison berries are used up, we all have to make do until the next harvest is on the books.

Most commodity flour is an assortment of commodity wheat, varieties grown for ease of harvest, ease of milling, ease of baking. These varietals are blended together so flour companies can sell the same product year after year. Grain is collected from around the globe and gathered at enormous mills then flattened, sifted and mixed into bags for consumers. The silos are never empty of grain to mill, specific varieties not a concern, just that similarities are such that the blending will go on unimpeded.

Using varietal grains, using grains grown for flavor, grown for their specific baking qualities, are missed when the supply is used up for the season. Last year, Cairnspring had to adjust its Trailblazer flour to Trailblazer Select, bringing in Skagit Red, a variety they found to mix with the dwindling supply of Yecora Rojo grain, that would provide the same great bread flour and the quality flavor. It has preformed beautifully. The increased demand for these beautiful flours has created a bit of a bind: there is only so much to go around.

I imagine it won’t be long until the big mills try to get on board the varietal flour train that’s been gaining momentum across the Country. They’ll give precious names to commodity wheat blends, trying to lure in some of this market segment willing to pay optimal prices for something so humble as flour. The truth will out in the products though. Just like the word “artisan” lost all meaning when companies using sourdough flavoring slapped that label on their bread bags, varietal wheat will go the same way. Bread made with actual wheat varietals, though, wheat grown by farmers whom I can actually name, will always be amazing.

The flavor, the texture, the real-ness of this food can’t be faked. It will be more expensive since farmers are getting a better price then what commodity markets will bear. That should be lauded. Next time you’re at your favorite bakery, ask what flours they use. I make bread and sweets supporting these regional growers. Know that when you buy our products, or those from any of the many bakers now using regional varietal wheat flour, you are helping out a farm family. Here’s to wheat!

The Queen of Bread

When Marie-Antoinette [supposedly] stated that the starving people of France should eat cake rather than bread, she was not the first to use such a phrase. Qu’ils mangent de la brioche has been found in writings before the doomed-queen’s time (McNamee). The word brioche is often translated as cake, but seems a far more insidious word choice.

We all know cake: light, sweet, often beautifully decorated, a luxury food, especially if made for royalty. Brioche, also light, just ever so sweet, but still bread, would be much more heartless for the queen to recommend to the starving populace. A people demanding bread. The King’s wife advising they eat enriched white bread, bread full of eggs and milk and sugar. A people with no bread, no eggs, no milk, told to eat bread made rich with those ingredients. It’s no wonder she lost her head.

Brioche is delicious food. Traditionally made from white flour, kneaded for a long time, even by machine, to develop the gluten to handle the softened butter added slowly at the end of mixing. Softened butter, not melty or greasy, fed into the whirling dough, more added only after each bit incorporated. That dough then let to rise at warm room temperature, refrigerated over night to develop flavor then shaped and eventually baked the next morning.

My brioche uses the high extraction Sequoia and Edison flours, creating even more flavor, flavor inherit in the wheat varietals themselves. While not fully fermented, I do use sourdough starter as part of the enrichment, giving the finished products a tinge of tang and longer shelf life. Moving baked goods away from pure white flour gives them more nutrition, more flavor. Taking that brioche dough and adding a bit more butter, along with some brown sugar and cinnamon, makes a cinnamon roll worthy of royalty but full of real-food flavor for the people. To me, brioche is a special occasion food, not daily bread. However, knowing there is a pan of cinnamon rolls in the freezer, means that a soon-to-be Sunday will indeed become a special occasion.

Bon appetit!

McNamee, Gregory Lewis and Blake, Susannah. “brioche”. Encyclopedia Britannica, https://www.britannica.com/topic/brioche. Accessed 20 January 2023.

Recent Comments